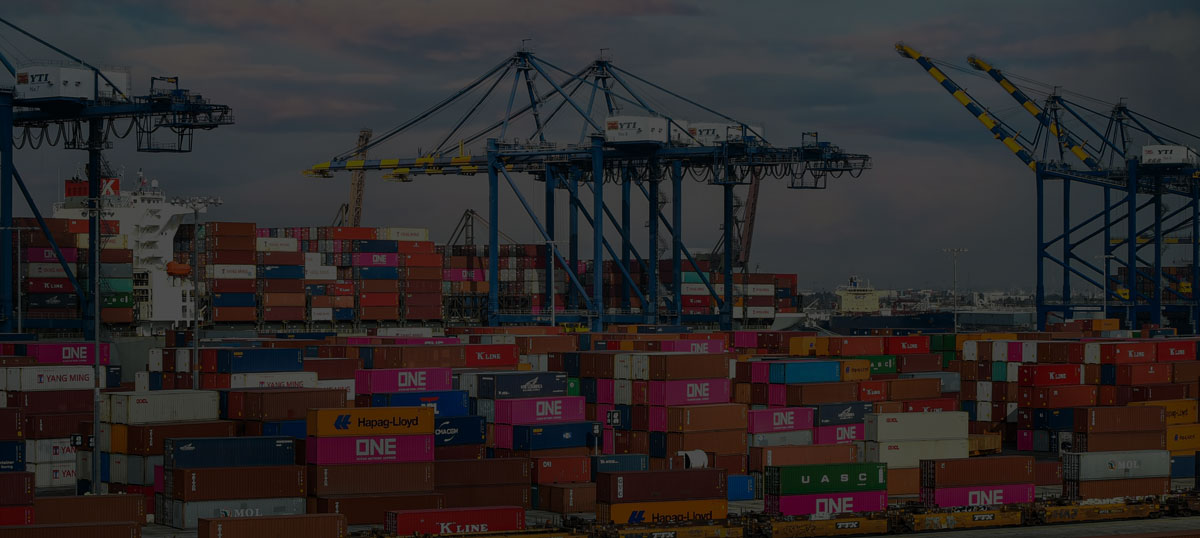

Global supply chains are more vulnerable than ever, and the recent port strike on the U.S. East and Gulf coasts brought these vulnerabilities into sharp focus. Tens of thousands of dockworkers went on strike for three days, causing significant delays for the $2 billion worth of goods flowing through these ports daily. While operations have resumed following a tentative wage agreement, the backlog of ships waiting to unload highlights the ongoing fragility of supply chains.

At Pacific Transformer, we understand how critical it is to maintain the flow of goods, especially when unexpected disruptions occur. That’s why we proactively take steps to ensure that our customers—whether you’re ordering custom power transformers or other critical components—are protected from the ripple effects of these disruptions.

The Impact of Supply Chain Disruptions

Supply chain issues can have far-reaching consequences. According to Accenture, such disruptions can erode a company’s share price by up to 7%. But for companies with diversified and adaptable supply chains, like those who rely on Pacific Transformer for custom power transformers, potential losses can be reduced by as much as 30% during regional disturbances (PwC).

These statistics highlight the importance of agility, flexibility, and proactive risk management in today’s volatile global landscape. When you partner with us for your custom power transformers, you’re choosing a team that understands these challenges and has the infrastructure to respond swiftly and effectively.

How Pacific Transformer Kept Your Supply Chain Moving

During the recent port strike, our team was already prepared before the first sign of disruption. Here’s how we ensured that your supply chain stayed intact:

- Early Identification of Risks

Our team closely monitored labor negotiations and port activities, recognizing the possibility of a strike early on. By staying ahead of the news, we could implement proactive strategies to mitigate potential delays. - Adjusting Production Schedules

Anticipating delays at the East and Gulf coast ports, we ramped up production at our facilities in Mexico and the U.S. This allowed us to increase supply and build buffer stock for our custom power transformers, ensuring we were ready to meet demand. - Rerouting Shipments

By leveraging our diversified manufacturing and logistics network, we rerouted shipments through unaffected ports. This minimized transit times and ensured that your products—including custom power transformers—arrived on schedule. - Cross-Location Coordination

Our global facilities worked in close communication throughout the strike, ensuring seamless operations across the board. This behind-the-scenes coordination allowed us to maintain normal production and delivery without disruption to your business.

Proactive Risk Management in Custom Power Transformer Supply Chains

One of the reasons we can maintain such high levels of service, even during unforeseen events like port strikes, is our commitment to proactive risk management. We continuously monitor global economic and political landscapes—whether it’s labor disputes, tariff changes, or geopolitical instabilities.

With our diverse manufacturing footprint across the U.S., Mexico, and Thailand, we can swiftly pivot operations to minimize the impact of these external factors. For instance, if tariffs were to rise on imported components, we could seamlessly shift production to our North American facilities, keeping costs low for your custom power transformer orders.

This flexibility, combined with our proactive approach to risk management, ensures that we can shield your business from supply chain disruptions while delivering the highest quality custom power transformers on time.

Why Custom Power Transformers Need a Resilient Supply Chain

Custom power transformers play a crucial role in industries ranging from renewable energy and utilities to defense and transportation. A delay in receiving the right transformer could stall projects, increase costs, and create downstream issues that affect your entire operation.

By choosing Pacific Transformer, you’re working with a company that understands the importance of maintaining consistent and reliable supply chain operations. We ensure that you receive the exact specifications for your custom power transformer needs, even during challenging times like the recent port strike.

The Pacific Transformer Advantage

In today’s unpredictable global market, having a resilient supply chain isn’t just a nice-to-have—it’s essential. Here’s why Pacific Transformer stands out:

- Diversified Global Footprint: With production facilities strategically located across North America and Asia, we have the ability to shift operations and avoid regional disruptions.

- Proactive Risk Management: Our team constantly monitors global trends and events, so we can adjust our strategies before disruptions impact your business.

- Expertise in Custom Power Transformers: Whether you need transformers for industrial applications, renewable energy systems, or defense projects, we design and deliver high-performance solutions tailored to your needs.

Conclusion: Partnering for Resilience and Reliability

The recent port strike may have caused major delays for many industries, but at Pacific Transformer, we made sure that your supply chain remained unaffected. Our approach to proactive risk management and diversified operations ensures that, no matter what challenges arise, your custom power transformers will be delivered on time and to your exact specifications.

If you’re looking for a partner who can keep your business running smoothly in the face of global uncertainties, look no further than Pacific Transformer. Contact us today to learn more about how our custom power transformers and resilient supply chain strategies can help you stay ahead of the competition.