We asked one of our lead engineers, what are the essential questions you ask when designing a custom power transformer?

He broke down these questions into five primary categories that cover 90% of the applications

1 – The Type of Transformer

What type of transformer does it need to be? The most common are:

- Single Phase

- 2-Phase

- 3-Phase

Don’t worry; we specialize in the not-so-common types as well.

2 – Primary (The Input Section)

- What is the input voltage?

- What is the input current?

3 – Secondary (The Output Section)

- What is the desired output voltage?

- What is the desired output current?

If the secondary is DC, what is the rectifier topology? The most common are:

- Full Wave Bridge

- Bridge

- Center-Tapped

- Single Phase

4 – Finish (The Connectors)

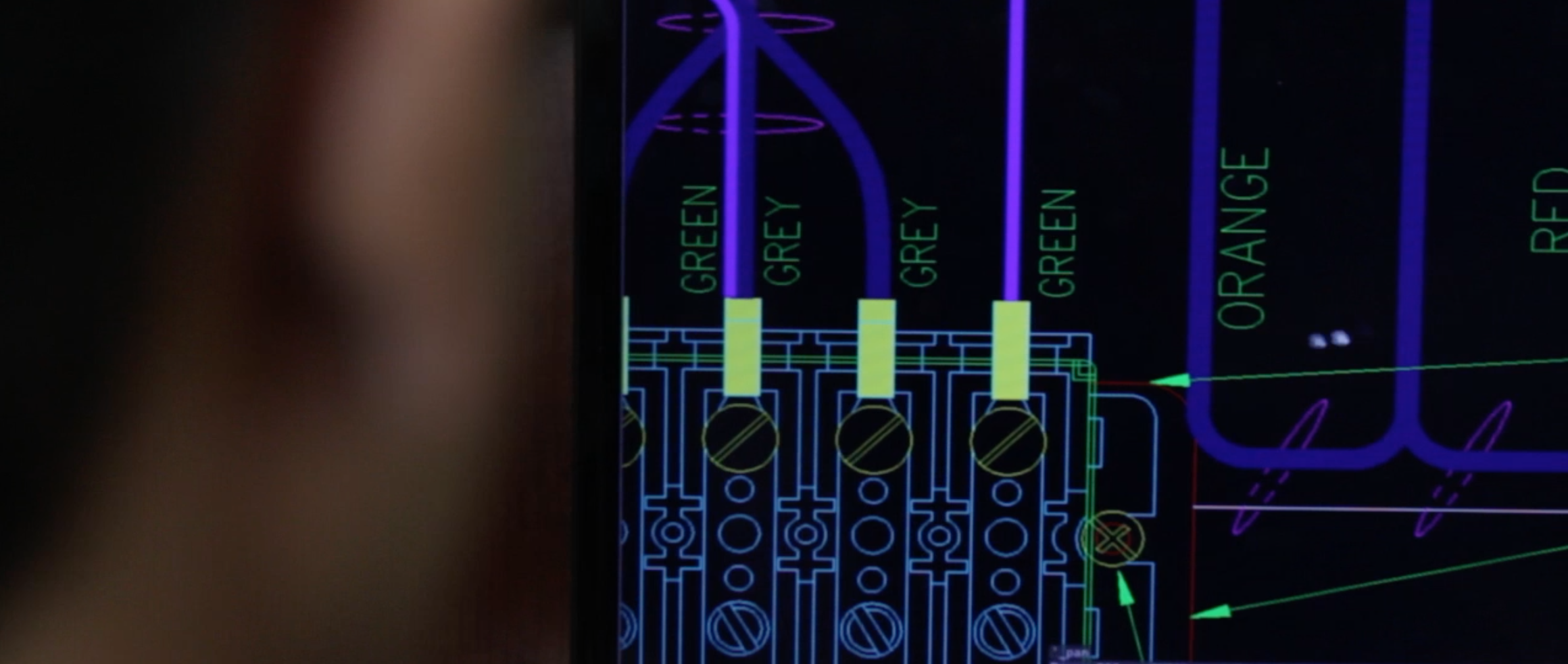

What type of connectors do you need for your application? The most common are:

- Wire leads

- Terminal Block

- Solder Lugs (Used primarily on PCB boards)

- Copper Terminals

5 – Geometry (The Size)

What is the desired size or the space restrictions of the transformer?

In more complex applications, there may be a few other considerations categories to discuss, such as:

Regulation

The voltage regulation of the transformer is the percentage change in the output voltage from no-load to full-load. Voltage regulation will vary as the power factor varies. The regulation is measured in percentage.

Temperature

- What is the ambient temperature range the power transformer will be working within?

- What is the maximum allowable temperature rise?

- Will there be any cooling?

Testing

Some applications will require additional testing to receive a particular certification. For example, many transformers built for defense require a MIL-SPEC certification, which subjects random samples to vibration testing.

Regardless of your project’s complexity, our engineering team has the expertise to design the ideal solution for your application.

OUR CUSTOM PRODUCTS

Toroidal Transformers

Low-Profile Transformers

International Power Transformers

Chokes

Coils

Inductors

Inverter Transformers

Switching Transformers

Isolation Transformers

WHY CHOOSE PACIFIC?

• Off Shore Pricing

• Risk-Free International Manufacturing

• Fastest Turn-Around Times

• No Job too Big or Small

• Free Designs and Prototypes

• Experts in Agency Approvals (UL)

Quality of the Highest Standard

When it comes to quality, some come close to our high standards but no one can beat us. We have spent decades devising a quality management system that ensures the highest standards possible. These quality standards have been independently audited and certified by the most demanding auditors and agencies. Organizations such as ISO, the International Aerospace Group and NSF International. We are also qualified by UL, CSA, ETL and TUV. We have over one million of our products on various military apparatuses. Medical equipment, satellites, railroad safety and traffic control all require the highest level of quality because there simply can be no failure.

Notable Custom Applications

![]() Our custom transformers are used on the majority of hardware used by our armed forces.

Our custom transformers are used on the majority of hardware used by our armed forces.

![]() We have designed and manufactured power solutions for almost every electric vehicle on the road today

We have designed and manufactured power solutions for almost every electric vehicle on the road today

![]() If you’re sitting in a dental chair in the United States, odds are a Pacific Transformer is in that chair.

If you’re sitting in a dental chair in the United States, odds are a Pacific Transformer is in that chair.

![]() We have designed and built over 1,000,000 units powering landscapes in the US

We have designed and built over 1,000,000 units powering landscapes in the US

![]() We helped develop the latest surgical knives and the original cochlear implants

We helped develop the latest surgical knives and the original cochlear implants